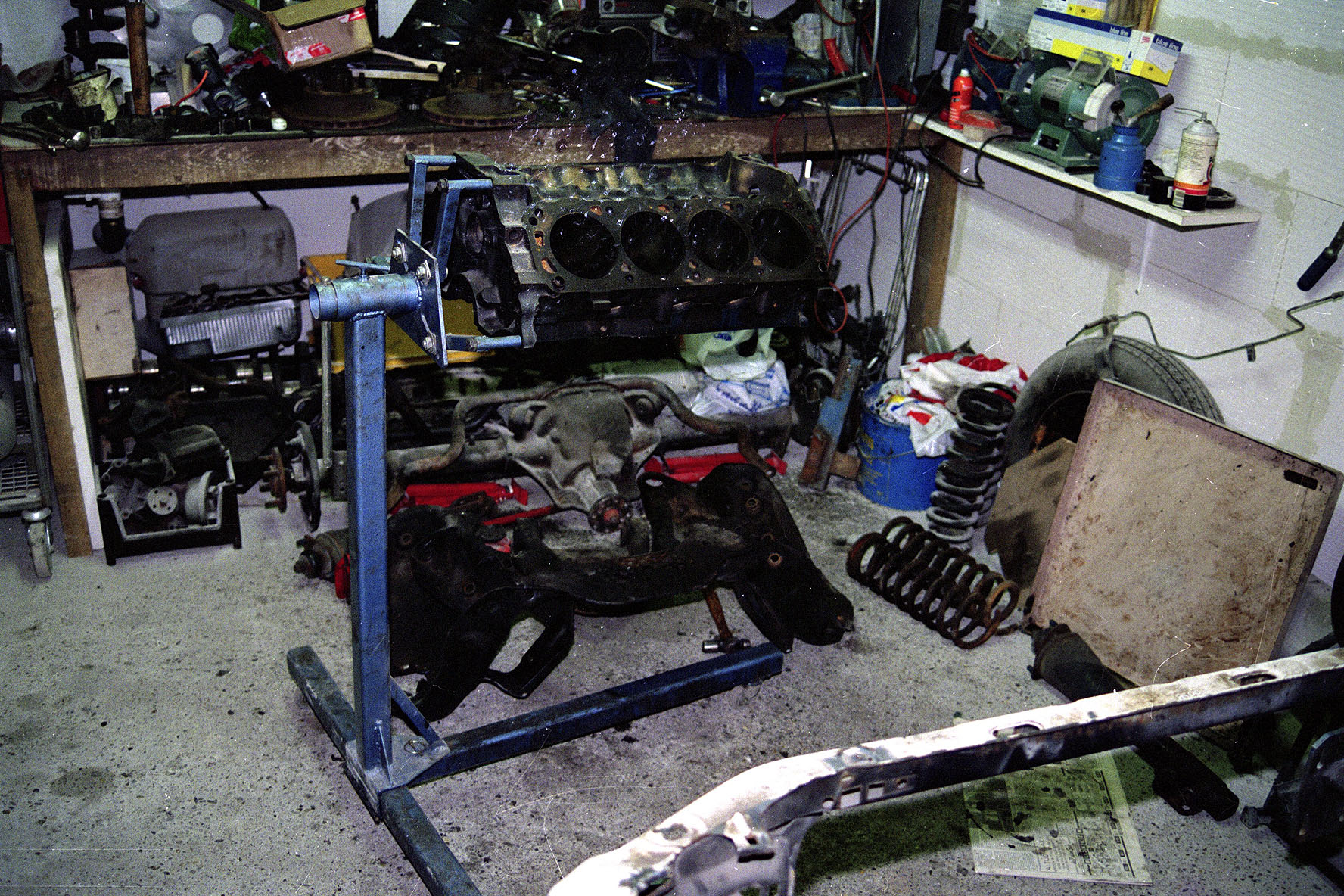

After starting to strip it down I found that the factory sunroof was completely rotten and unrepairable, the only answer was a new roof. So a new roof was sourced from a scrap yard and the delicate process of cutting off the old one was started. The photo’s also show just how little room I had in my garage at the old house, the car only fitted if the nose went under the workbench.

Before cutting the old roof the car was supported on two thick wooden beams running the length of the car on each side, some careful measuring was necessary to ensure that the new roof fitted in exactly the same position as the old.

Most of these pictures were taken with an old polaroid camera which I had lying around, or a small 35mm Canon compact, so the quality is not that good and they are all quite small format. Here are a couple of close ups of the roof work.

The pillars are all braced behind the weld with pieces cut from the profile from the old roof giving some extra strength and also something to weld against. Shame there are no Photo’s to show it. After welding the centre pillars the beams were removed from under the car to put it back on it’s wheels. This pushed the front and rear pillar halves together so they could also be welded, this recreated the structural integrity of the roof.

That completed I moved on to the front end which was completely stripped out and all surface rust removed. If you look carefully you can see that it is sitting on the modified lower section of an old damaged shopping trolley. The reasonably sized caster wheels made it possible to push the shell in and out of the garage to work on it.

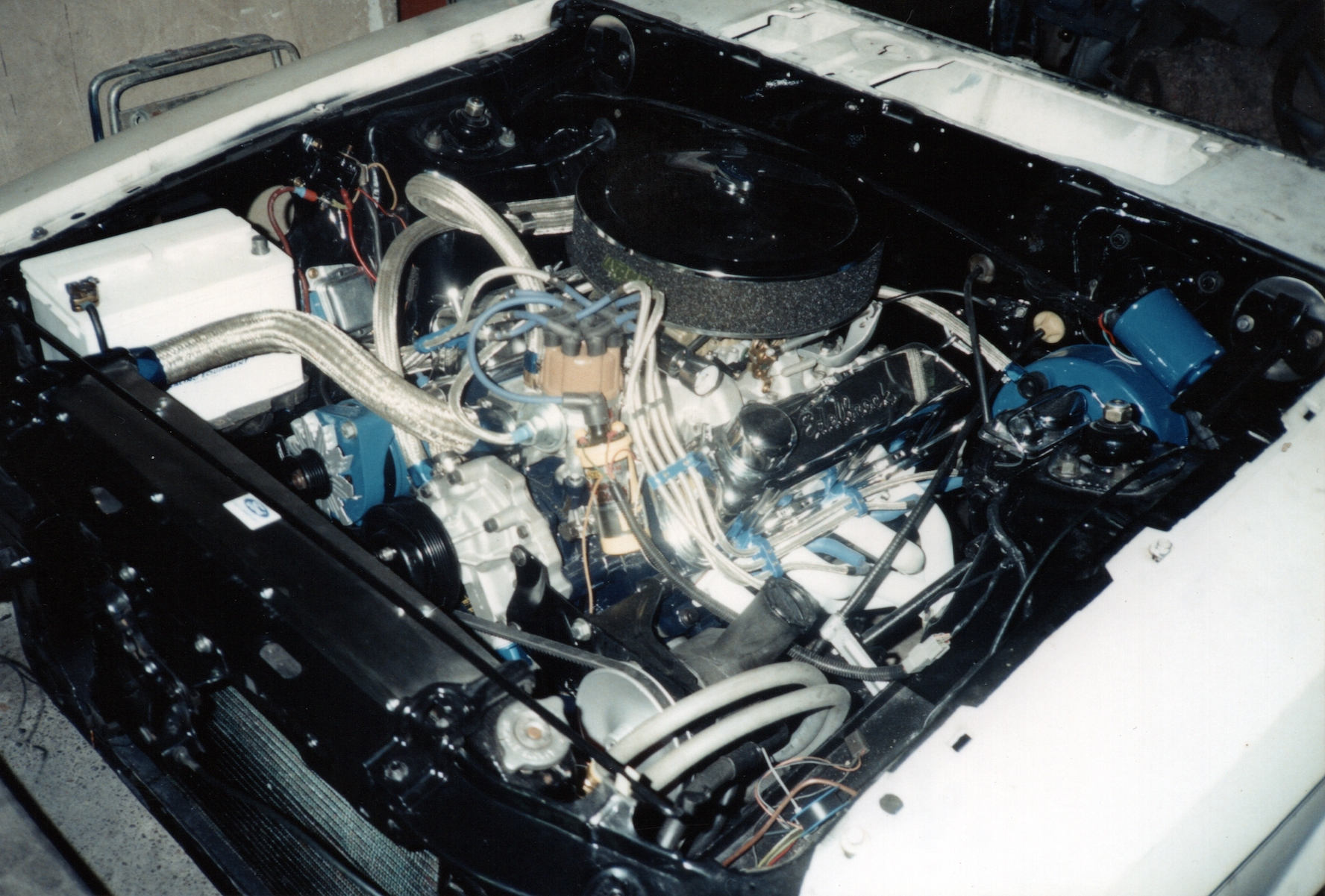

Again no pictures of any of the work after this until I’d finished the front end and was just about ready for the engine to be refitted.

It is still sitting on the trolley but the struts have been re-installed.

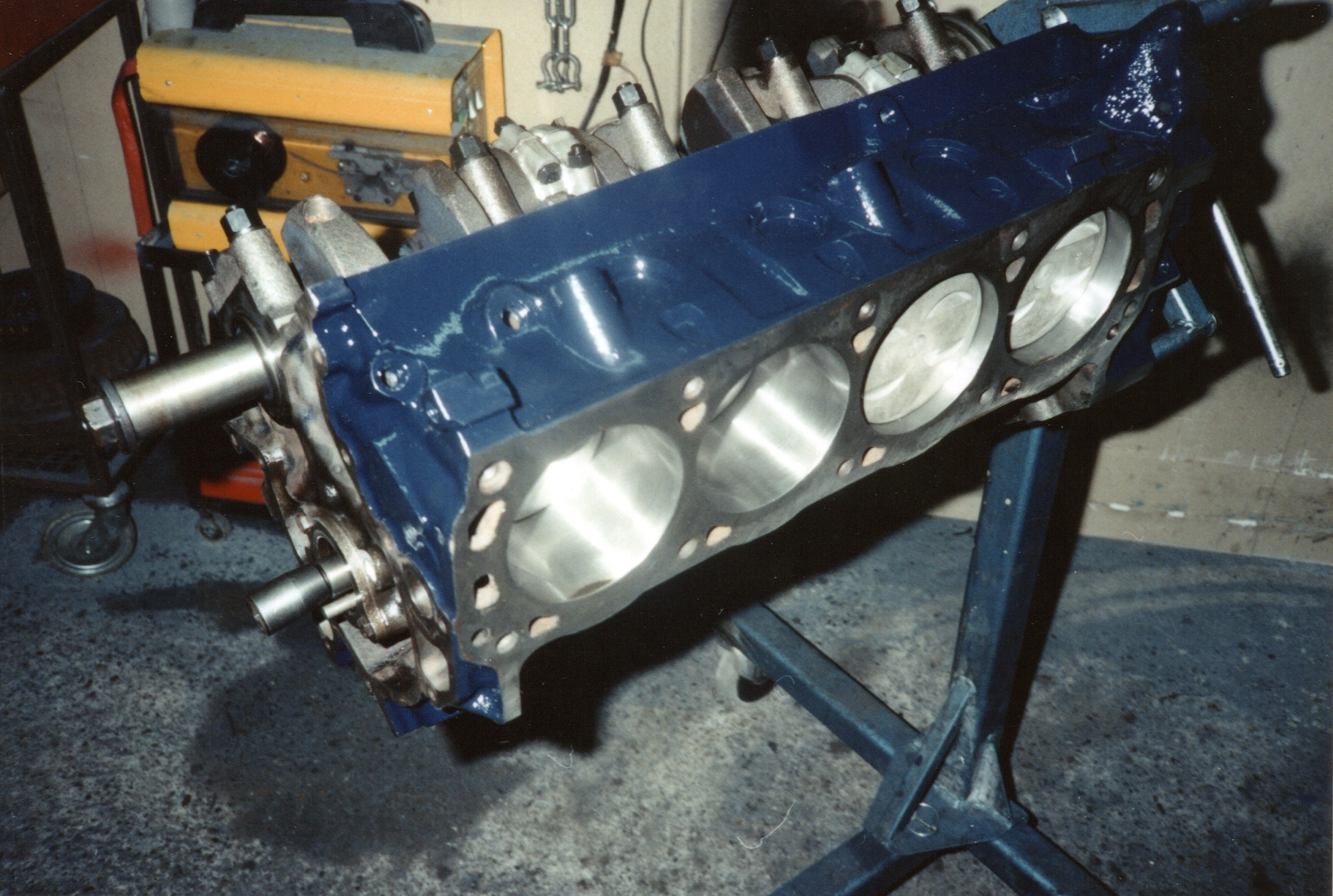

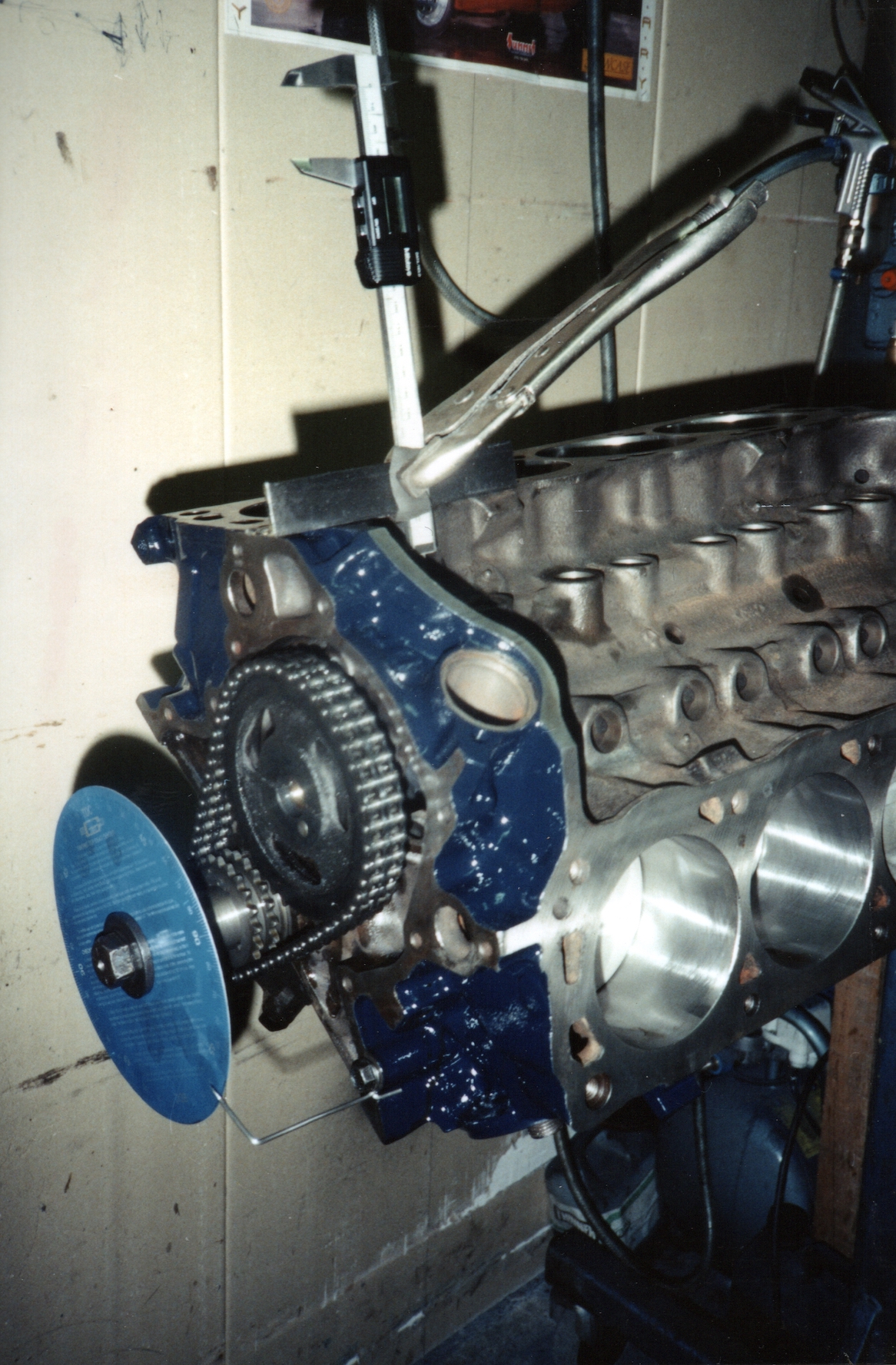

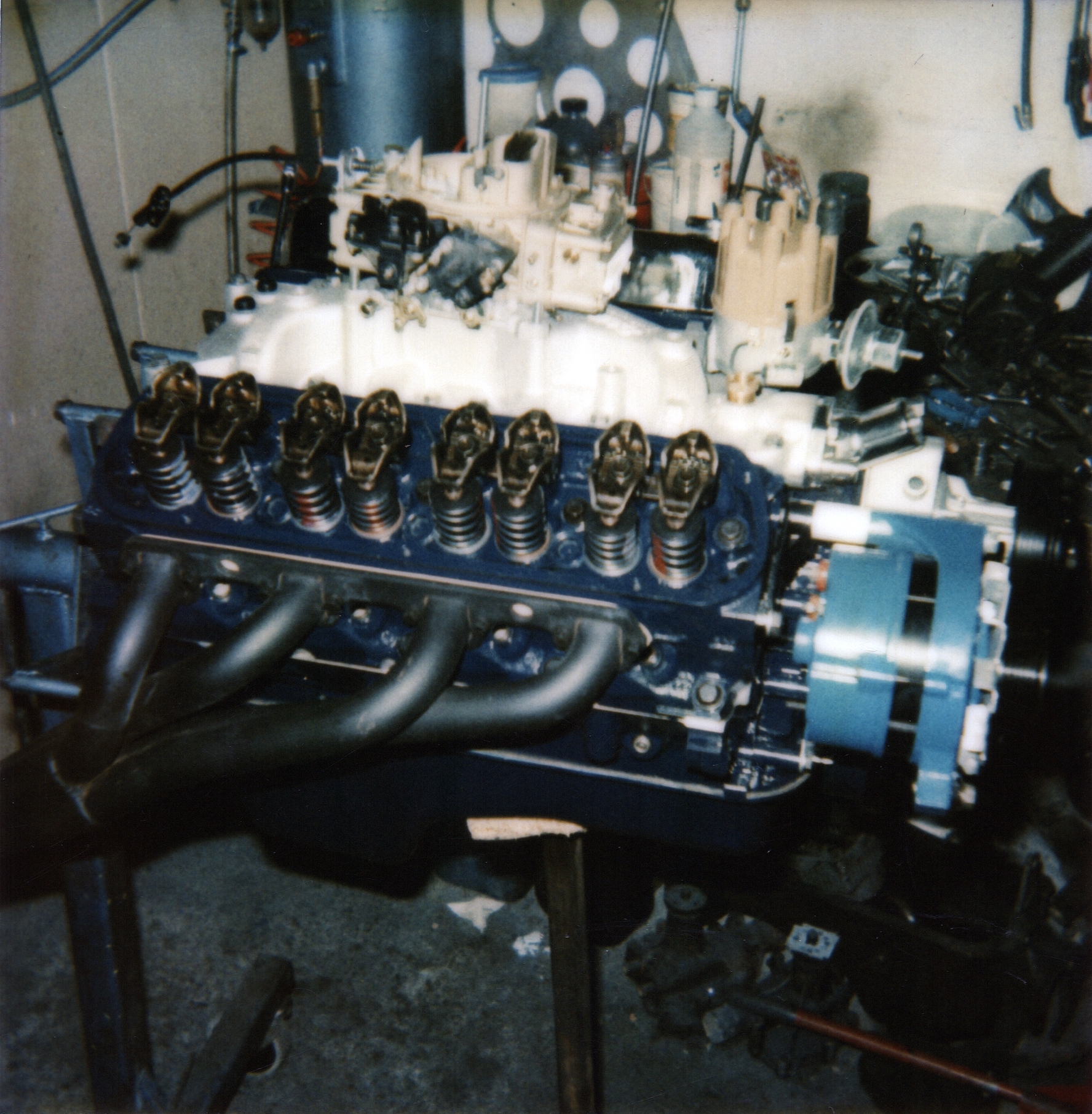

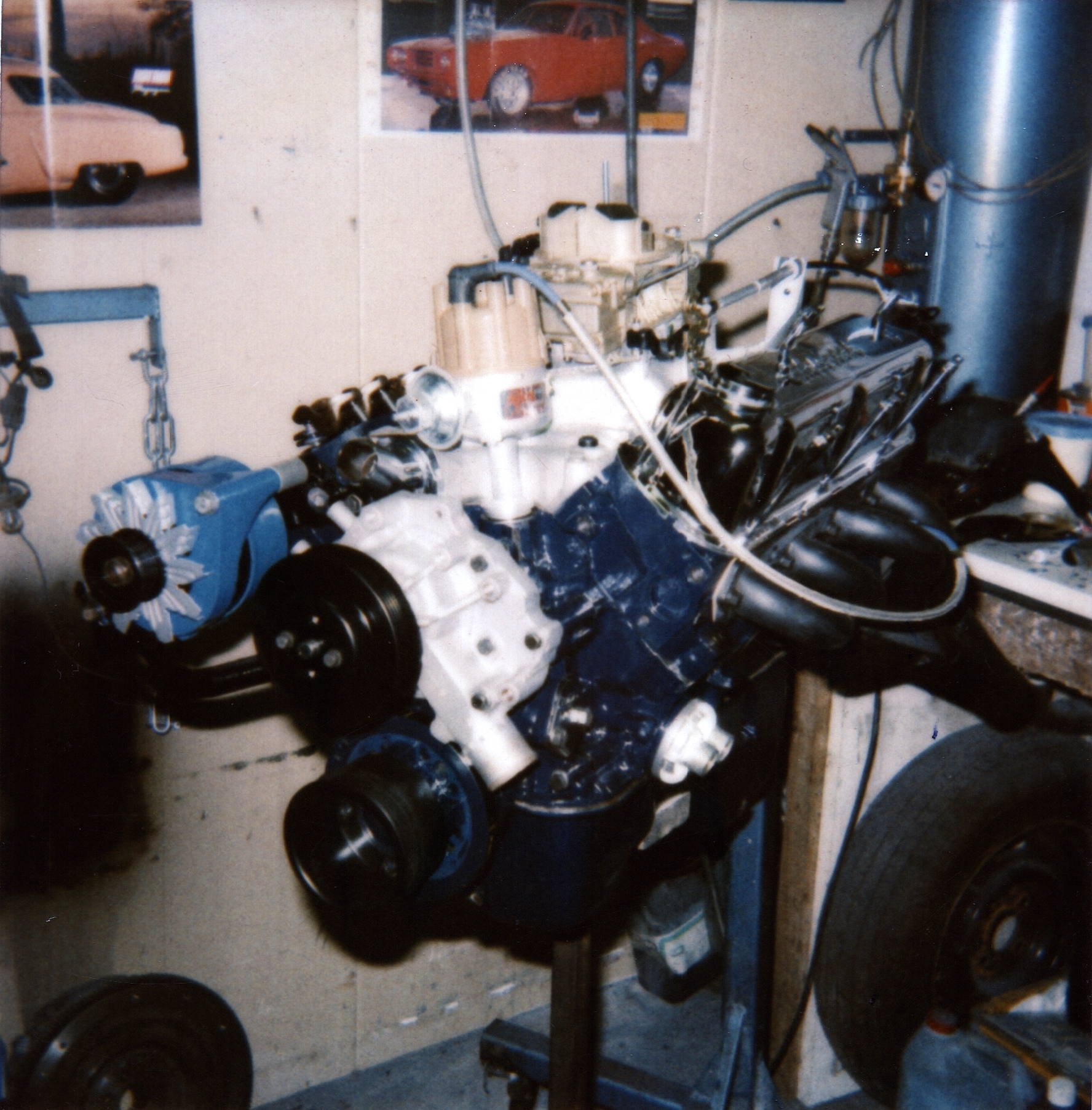

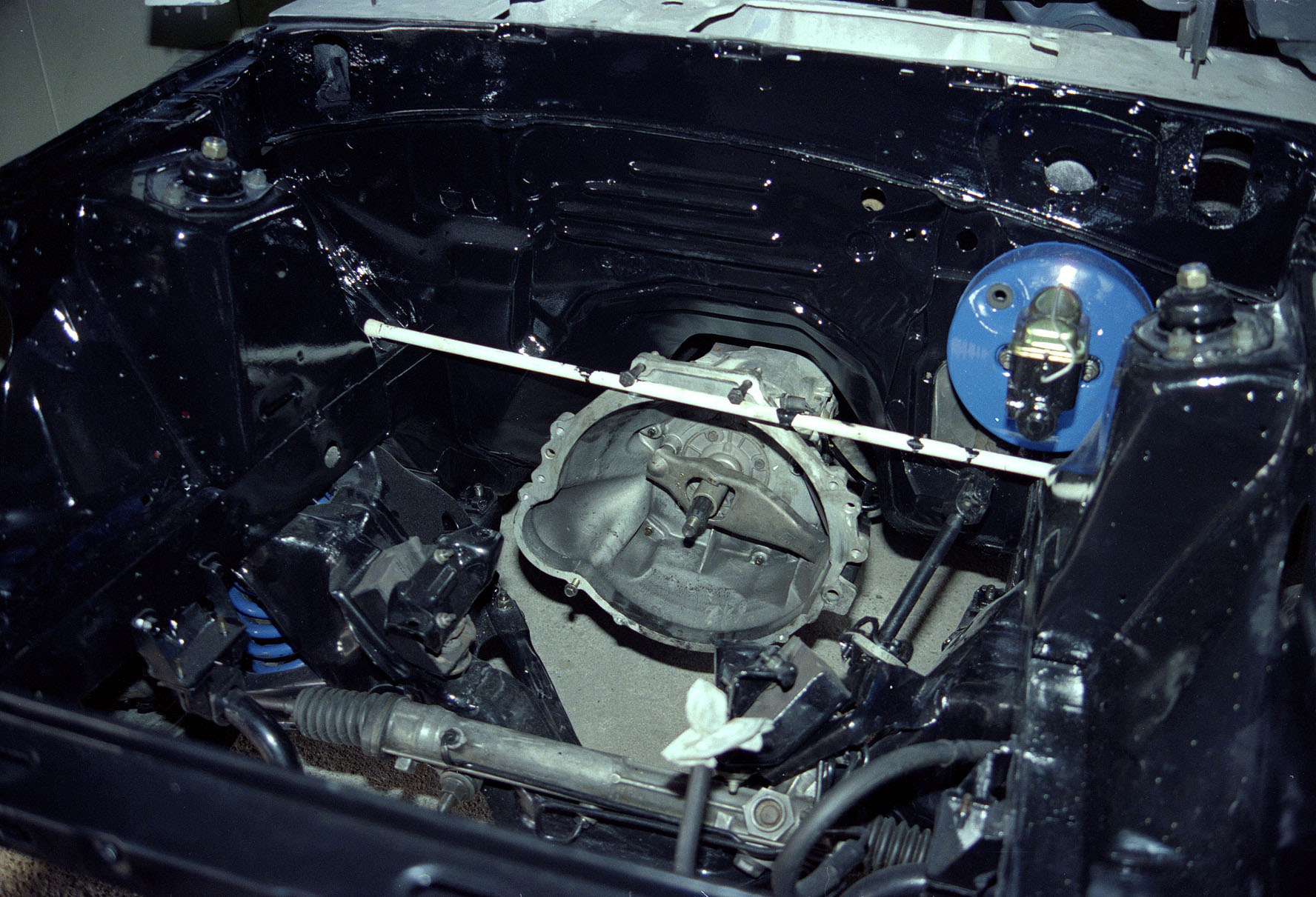

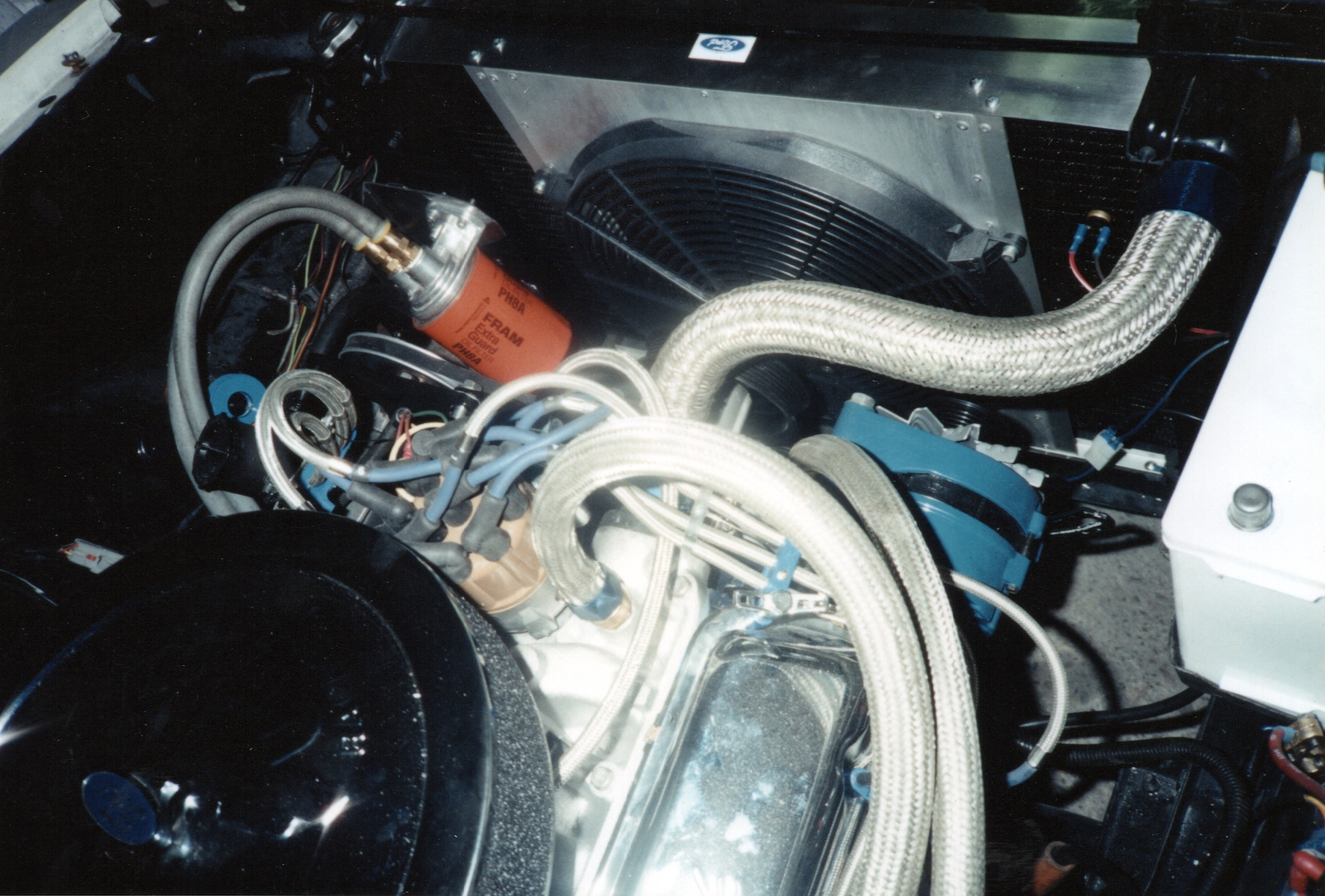

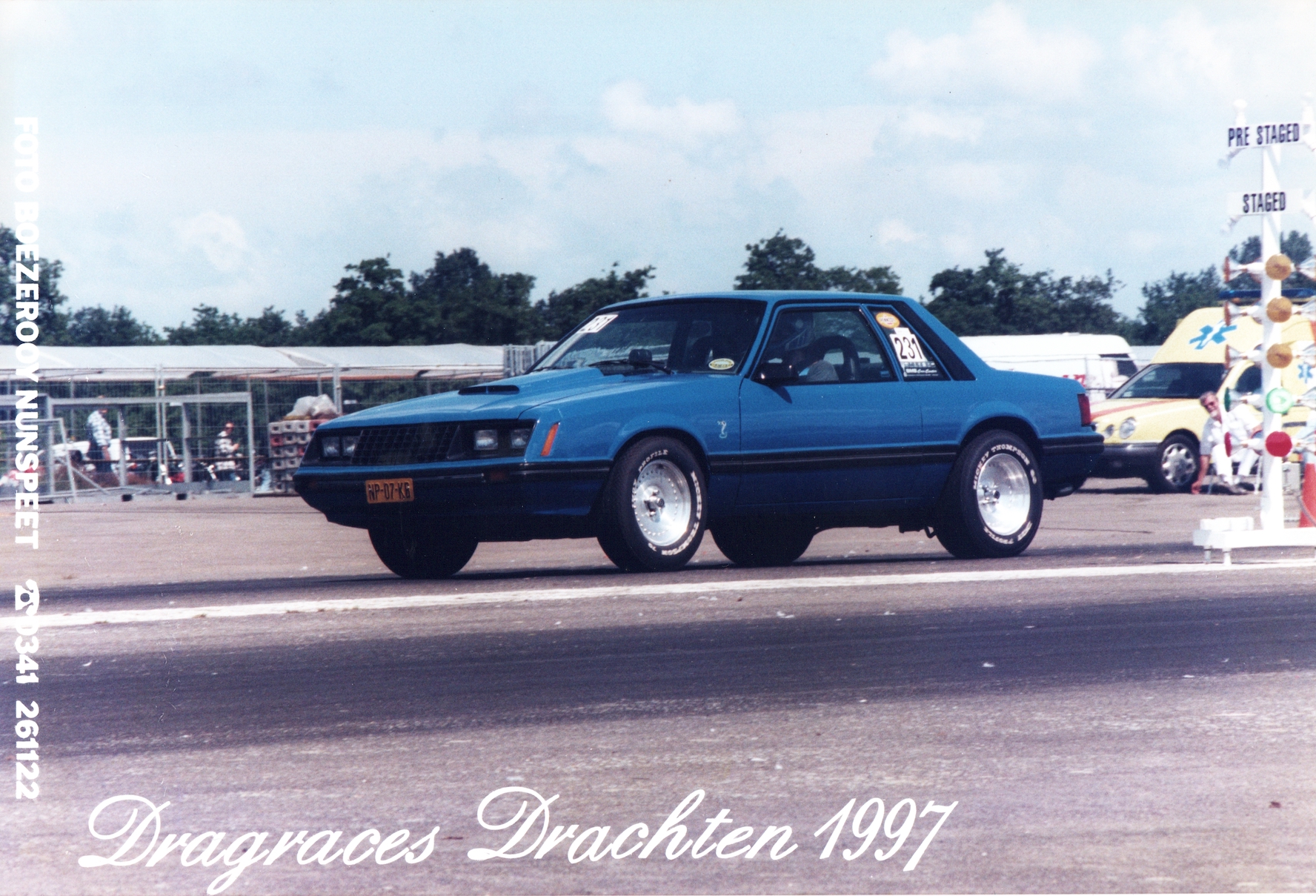

Having made plans to get much more power out of the engine than it had ex factory (would you believe that 140hp was all it produced!!), I had sourced a totalled ’87 Mustang GT at a breakers and got a good deal on the transmission (Borg Warner T5), rear axle with LSD, springs and brakes (bigger than my originals). The shocks were changed to Koni’s all round and all suspension rubbers were replaced with polygraphite bushes which give much better stability at the sacrifice of ride comfort. Goodridge brake lines all round as well. Another leap in time to the rear axle which was done in a similar fashion with the front wheels back on and the trolley supporting the rear.

The original rear suspension arms were replaced with Southside Machine Lift Bars to get that bite necessary for drag racing. Yes by this time the project had started to snowball into a near full blown drag car, at least as far as it was possible within the law in the Netherlands for a road going car. These bars have NO rubber bushings but instead steel bearings giving incredible straight line stability but again sacrificing ride comfort.