This work was undertaken in the winter stop period of 2015 and was initially one of the blog pages.

Before Christmas I was busy doing some online shopping to get hold of the gauges and the Miller WAR programmable chip. The Toad Alarm system I bought last year when we were in England. The set of gauges included an oil pressure gauge, oil temperature gauge and a volt meter but after the WAR chip arrived I decided to get an AEM Wide Band UEGO O2 sensor and gauge to help me with the chip programming (it measures the fuel/air ratio), So after everything arrived I first set about stripping out the old alarm and the wiring behind the centre console for the radio which was also in a bit of a state from previous owners. I had been thinking for a while about a design to fit the gauges in the lower part of the centre console where the original cassette holders were situated. I also decided to replace the ashtray and lighter which are situated in the horizontal section in front of the cassette holder. After removing these sections I made templates from some cardboard packaging.

From the two templates I created a single section from MDF to fit in the space.

After a certain amount of adjustment and trial and error I got it to fit reasonably but not quite as I wanted it. The two holes were just to put my finger and thumb through to pull it into place. Not being completely happy I decided to remove the centre console completely, making access from the rear much easier than the turn and twist from the front.

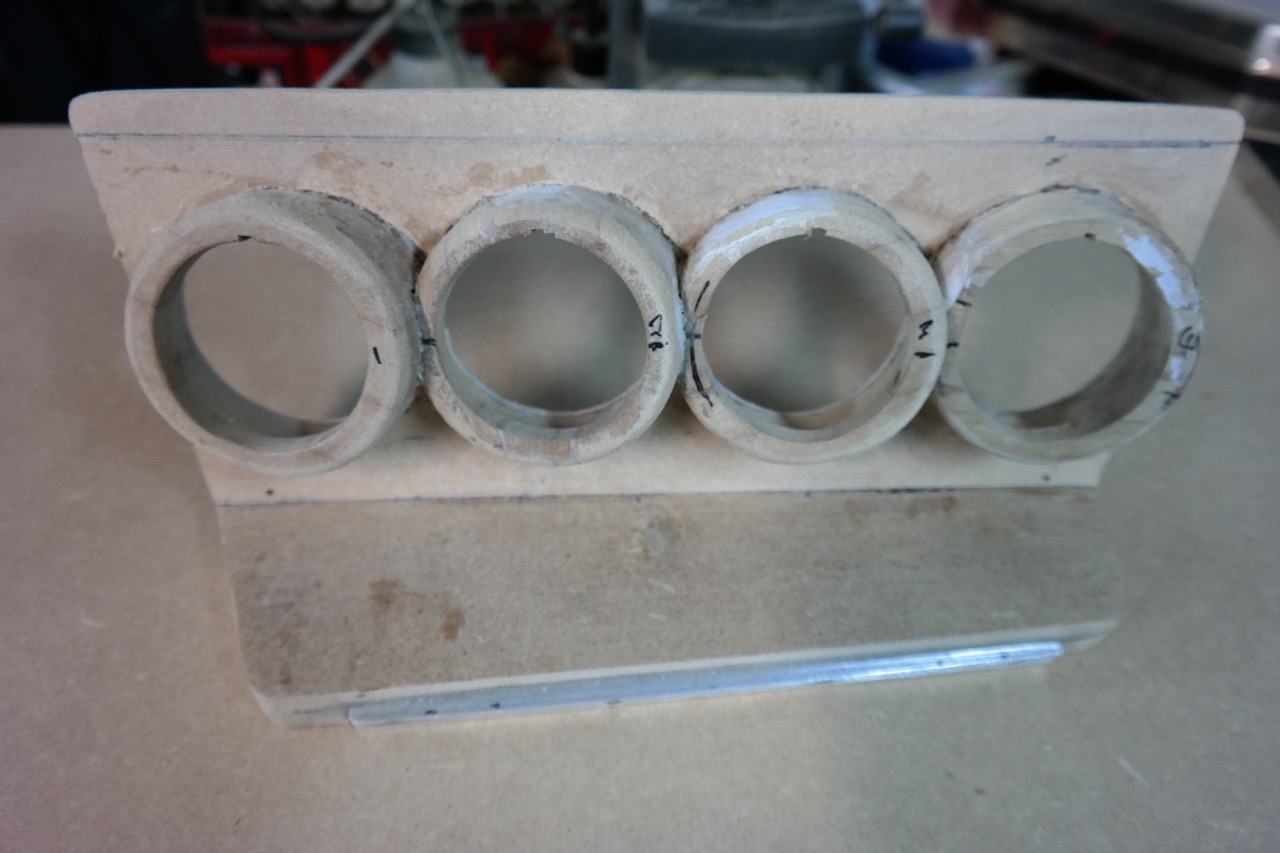

The next step was the the fitting of the gauges. It would have been simple to just cut some holes in the panel and job done but I had earlier realised that the visibility wouldn’t have been brilliant as they sit so low. They needed to be turned slightly upward and to the left and I first thought about making square box like sections to attach to the front. After playing around with a cardboard mockup I decided that it looked bit naff and decided to try and do something like the windscreen post pods which are available. What I needed was an MDF tube but nothing like that is available so I had to make my own. Step 1 glue some pieces of MDF together and let it dry overnight (sorry, too busy, forgot the photo’s again). Step 2 find the centres at the two ends and mount it in the lathe. Step 3 turn it into a solid cylinder. Step 4 divide it into four sections and using a fine blade as it turns in the lathe cut partly through each of the three cuts, finish the cuts off the lathe. Step 5 hollow out each section to the diameter necessary to allow the rear attachment, and here’s a photo (the duct tape is just to protect the surface a bit from the chuck jaws).

The mole wrench attached to the bed is just a quick fix to create a stop for the carriage so that I left the correct lip thickness to mount the gauge in place. The next photo shows a couple of the pods after completing this step. You can see the material left on what would be the front.

Step 6 is to put the pods back in the lathe and finish off the front so that the gauge fits. Round off the edge with some sandpaper to create the correct shape and the lathe work was finished.

Step 7: Create the correct angle to the back of the pod plus the shape to fit them together on the belt sander (again no photo’s, too much mess). Step 8: place the pods together on the front of the replacement lower panel and draw round them with a fine tip marker. Step 9: I machined around the inside of the marked lines on the milling machine to about half the thickness of the panel. All done slowly by hand as it’s not a CNC. This was done to create a better bond between the pod and the panel. After glueing and holding in place with some duct tape to dry overnight it looked like this.

Just a question of finishing now. After cleaning the glue off it started to look like it might be something and I made a start at getting it into shape with some polyester filler.

The back needed some extras to help mount the cigarette lighter (on the left) which I decided to keep rather than build in just a USB adapter. Also the control for the sub woofer and the rotary switch for the WAR chip tune selection. I needed to sink the knobs because the shafts wouldn’t fit on the 5mm thickness of the panel. Best solution seemed to be the aluminium strip which doubled as extra support for the sub control.

After priming plus liberal coats of spray filler and much sanding we were getting there.

A last trial fitting before some colour was applied and it was beginning to look like what I’d seen in my mind’s eye.

The initial result after spraying with matt black just didn’t look right, for one thing the paint wasn’t matt it had a slight shine which just didn’t look right with the rest of the dashboard. I ended up creating a textured finish by blowing some of the sawdust I’d created onto the wet paint and as it dried brushing off the excess.

After a bit of judicial work with some Scotchbrite it eventually seemed to be part of the interior. This is what it will look like when it gets replaced in the car although the console will need a bit of a polish of course.

After all that the workshop needed a lot of clearing up so I spent one evening with the vacuum cleaner, broom and dustpan and brush so I could begin with the electrics. Below you can see that I’ve been busy making a mini wiring loom which will attach to the rest of the electrics under the dash with the multi-plug. A few more wires to attach but it’s as good as finished and I can move on to the next job. Haven’t made up my mind if that’s going to be the alarm or the WAR chip upgrade.

Post Script: Wasn’t very satisfied with the Equus gauges I initially bought – cheap doesn’t cut it. So I bought a set of VDO and sold the Equus set.